In a world where precision is key, one often overlooked hero silently spins into action: the electric motor. These humble powerhouses may not get the recognition they deserve, but behind the scenes, they’re busy tailoring their skills to tackle the most intricate tasks with the utmost finesse. Join us as we dive into the fascinating world of tailoring electric motors for precision tasks, where every volt counts and every rotation matters. So buckle up, because things are about to get electrifyingly precise!

Optimizing Motor Size and Power

When it comes to , you want to make sure you’re not compensating for anything, if you know what I mean. Bigger isn’t always better, despite what your high school crush might have told you. Here are a few tips to help you find the perfect balance for your motor:

- Consider the task at hand – does your motor really need to be the size of a small elephant, or is a cute little hamster motor more practical?

- Think about efficiency – do you really want to be the one draining the power grid just to show off your motor muscles?

- Don’t be afraid to consult with experts – sometimes it takes a village to find the perfect motor fit. And hey, who doesn’t love a little free advice?

Remember, when it comes to motor size and power, it’s all about finding that sweet spot. You don’t want to be known as the person with the obnoxiously overpowered motor that shakes the entire neighborhood every time it’s turned on. Take a few deep breaths, do some research, and find the motor that’s just right for you.

And hey, if all else fails, just close your eyes and pick a number out of a hat. It worked for your cousin when he picked his motor, right? (Just kidding. Please don’t take motor advice from your cousin.)

Implementing High-resolution Control Systems

Are you tired of low-resolution control systems that can barely keep up with your high-tech needs? Say goodbye to pixelated performance and hello to crystal-clear control with our high-resolution control systems!

With our cutting-edge technology, you can now enjoy smooth and precise control over every aspect of your system. No more blurry images or laggy responses – just pure, high-definition control at your fingertips.

Our high-resolution control systems are designed to make your life easier and more efficient. From advanced user interfaces to lightning-fast response times, you’ll wonder how you ever lived without it. So why settle for mediocrity when you can have perfection?

Upgrade to our high-resolution control systems today and experience the difference for yourself. Don’t let outdated technology hold you back – embrace the future with bold, crisp, and flawless control. Your system will thank you!

Accuracy“>

Accuracy“>

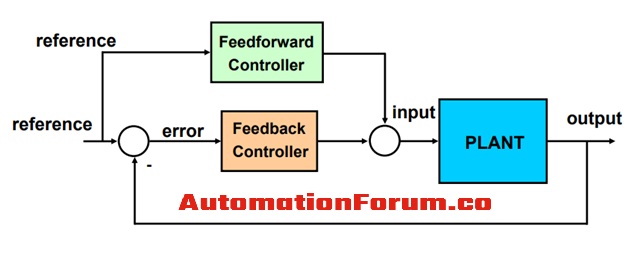

Incorporating Feedback Sensors for Accuracy

So you’ve decided to take your accuracy game to the next level by incorporating feedback sensors – congrats! These little gadgets are like your trusty sidekicks, keeping you on track and making sure you hit the bullseye every time. But before you dive in, here are a few tips to make the most out of your new teammates:

- Get to know your sensors like they’re your best friends – because, let’s face it, they basically are. Take the time to understand how they work and how they can help you improve your accuracy.

- Calibrate, calibrate, calibrate! Just like how you need to stretch before a workout, your sensors need to be properly calibrated to give you the most accurate readings. Trust us, it’s worth the extra effort.

- Don’t be afraid to experiment and fine-tune your setup. Play around with different settings and configurations to see what works best for you. Remember, it’s all about finding that sweet spot.

And last but not least, don’t forget to show your sensors some love. After all, they’re the ones helping you hit those bullseyes with pinpoint accuracy. Treat them right, and they’ll never let you down. Happy shooting!

Torque-vs-Speed-Curve.jpg” alt=”Fine-tuning Speed and Torque for Specific Applications”>

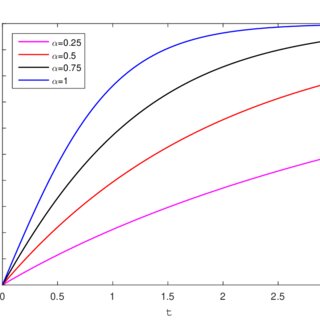

Fine-tuning Speed and Torque for Specific Applications

So you’ve got a specific application in mind and you need to fine-tune the speed and torque of your equipment to make it work juuuust right. It’s like trying to find the perfect balance between drinking coffee and not shaking like a leaf in a windstorm.

Well, fear not, dear reader, because we’ve got some tips for you on how to make your equipment purr like a kitten on a sunny day. Just remember, this is not a one-size-fits-all situation – you’ll need to experiment a bit to find the sweet spot.

First things first, consider adjusting the speed settings on your equipment. Slow it down or rev it up, depending on what your application calls for. It’s all about finding that Goldilocks zone - not too fast, not too slow, but just right. Remember, you can always use bold trial and error to figure out what works best.

Next, let’s talk torque. Adjusting the torque can be like finding the perfect amount of ketchup for your fries – too little and it’s disappointing, too much and it’s overwhelming. You want to find that sweet spot where your equipment can handle the load without breaking a sweat. Play around with the settings until you find what works best for your specific application.

Customizing Motor Mounting and Integration Solutions

Have you ever struggled with finding the perfect motor mounting solution for your project? Look no further! Our team of experts specializes in that will make your life easier and your project run smoother than ever before.

With our innovative approach to problem-solving, we can create a tailored solution that fits your specific needs and requirements. We don’t believe in a one-size-fits-all approach – instead, we take the time to understand your project and deliver a solution that is truly unique.

When you work with us, you can expect top-notch customer service and a quick turnaround time. Let us take the stress out of motor mounting and integration so you can focus on what really matters – bringing your project to life.

Don’t settle for subpar motor mounting solutions – choose us for a customized approach that will exceed your expectations. Contact us today to learn more about how we can help take your project to the next level!

Maximizing Efficiency and Performance through Precision Engineering

Imagine a world where every cog, bolt, and gear work together in perfect harmony to create a symphony of efficiency and performance – that’s the power of precision engineering! With cutting-edge technology and expert craftsmanship, we can optimize your systems to run like a well-oiled machine.

At the heart of precision engineering lies attention to detail and a keen eye for perfection. Our team of engineers are like the Sherlock Holmes of the mechanical world, uncovering inefficiencies and fine-tuning every component to ensure maximum output. No stone is left unturned, no screw is left unadjusted!

With precision engineering, you can say goodbye to downtime and hello to seamless operations. Our methods are tried and tested, guaranteed to squeeze every drop of productivity out of your machinery. Whether it’s reducing friction, minimizing wear and tear, or maximizing energy efficiency, we’ve got you covered.

So why settle for mediocrity when you can have excellence? Embrace the power of precision engineering and watch your business soar to new heights. You’ll be amazed at the difference a little bit of precision can make!

FAQs

How can electric motors be tailored for precision tasks?

Electric motors can be tailored for precision tasks by adjusting key components such as the voltage, current, and rotational speed to match the specific requirements of the task at hand. These adjustments allow for more precise control and increased efficiency.

What are some common precision tasks that require tailored electric motors?

Some common precision tasks that require tailored electric motors include robotic surgery, 3D printing, and precision machining. These tasks demand high levels of accuracy and control, which can be achieved through customization of the electric motor.

How does tailoring an electric motor for precision tasks improve performance?

Tailoring an electric motor for precision tasks improves performance by ensuring that the motor operates at its optimal efficiency for the specific task. This can result in smoother operation, increased precision, and reduced energy consumption.

Are there any drawbacks to tailoring electric motors for precision tasks?

While tailoring electric motors for precision tasks can offer many benefits, there are some drawbacks to consider. Customization can be more costly and time-consuming than using off-the-shelf motors, and maintenance and repairs may be more complex due to the specialized components.

What are some tips for selecting the right electric motor for a precision task?

When selecting an electric motor for a precision task, it’s important to consider factors such as the required torque, speed, and control capabilities. It’s also helpful to work with a knowledgeable supplier who can assist in customizing the motor to meet the specific needs of the task.

—

In Conclusion: Shockingly Good Results!

And there you have it! Tailoring electric motors for precision tasks may sound like a daunting endeavor, but with the right knowledge and approach, you can electrify your way to success. Remember, when it comes to precision tasks, never underestimate the power of a well-tailored electric motor. So go ahead, spark some creativity, amp up your efficiency, and drive your projects to electrically charged perfection!